PRODUCTS

Categories

Hot Products

Impact Idler Roller

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

Impact idler roller for Belt Conveyor is a type of idler rollers used in belt conveyors to support the conveyor belt and absorb impact from materials being loaded onto the belt. Impact Idlers for Belt Conveyor are designed with a rubber or urethane disc located at the center of the roller, which helps to cushion the impact of heavy materials and prevent damage to the belt. Impact idler set are typically used in areas where the material being conveyed is heavy or abrasive, such as in mining, quarrying, and construction applications. They are an important component of belt conveyor systems, helping to ensure safe and efficient material handling.

Impact idler roller for Belt Conveyor is a type of idler rollers used in belt conveyors to support the conveyor belt and absorb impact from materials being loaded onto the belt. Impact Idlers for Belt Conveyor are designed with a rubber or urethane disc located at the center of the roller, which helps to cushion the impact of heavy materials and prevent damage to the belt. Impact idler set are typically used in areas where the material being conveyed is heavy or abrasive, such as in mining, quarrying, and construction applications. They are an important component of belt conveyor systems, helping to ensure safe and efficient material handling.

WHERE IS IT USED

Impact idler roller for belt conveyor are typically used in areas where the material being conveyed is heavy or abrasive, such as in mining, quarrying, and construction applications. Impact Idlers for Belt Conveyor are commonly used in the loading zones of belt conveyors, where heavy materials are loaded onto the conveyor belt. The impact idlers help to absorb the impact of the materials and prevent damage to the belt, as well as reduce spillage and dust emissions. Rubber disc impact conveyor idlers are also used in areas where the conveyor belt is subjected to high levels of stress, such as in transfer points and areas where the belt changes direction.

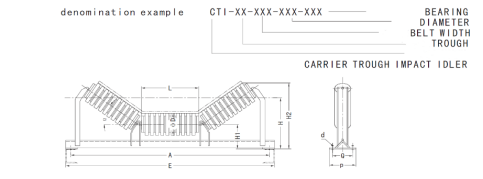

PRODUCT DESIGN

The design principle of Impact idler roller for belt conveyor is to provide a cushioning effect to the conveyor belt and reduce the impact of heavy materials on the belt. This is achieved through the use of a rubber or urethane disc located at the center of the roller, which absorbs the impact of the material and prevents damage to the belt.

The design of Impact idler set also takes into consideration the weight and size of the material being conveyed, as well as the speed of the conveyor belt. The roller shell is typically designed to be larger and heavier than standard idlers, in order to provide additional support and stability to the conveyor belt.

In addition, the bearings used to support the roller shell are typically designed to be more durable and resistant to wear and tear, in order to withstand the high levels of stress and impact that are common in heavy-duty applications.

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

1 The structure of impact idlers for belt conveyor typically consists of a steel or aluminum roller shell, which is mounted on a shaft and supported by bearings.

1 The structure of impact idlers for belt conveyor typically consists of a steel or aluminum roller shell, which is mounted on a shaft and supported by bearings.

2 The roller shell is designed with a rubber or urethane disc located at the center of the roller, which helps to cushion the impact of heavy materials and prevent damage to the belt.

3 The rubber or urethane disc is typically made of high-quality materials that are resistant to wear and tear, and can withstand the impact of heavy materials without degrading over time.

4 The roller shell is typically made of high-strength steel or aluminum, which provides excellent durability and resistance to corrosion.

5 The shaft is also made of high-strength steel or aluminum, and is designed to provide excellent support for the roller shell.

6 The bearings used to support the roller shell are typically sealed and lubricated, which helps to prevent contamination and extend the life of the bearings.

TABLE OF TECHNICAL CHARACTERISTICS

| BELT WIDTH | MODEL | ROLLER | BEARING No. | A | E | H | H1 | H2 | P | Q | d | MASS (Kg) | ||||||

| MODEL | D | L | 30 | 35 | 45 | 30 | 35 | 45 | ||||||||||

| 500 | -343 | CIR-89-204-200 | 89 | 200 | 204 | 740 | 800 | 220 | 135.5 | 286 | 300 | 328 | 170 | 130 | M12 | 17.6 | 18 | 18.6 |

| 650 | -358 | CIR-89-204-250 | 89 | 250 | 204 | 890 | 950 | 235 | 135.5 | 311 | 329 | 364 | 170 | 130 | M12 | 21.1 | 21.2 | 21.7 |

| -359 | CIR-89-205-250 | 205 | 23.4 | 23.5 | 24 | |||||||||||||

| -377 | CIR-108-204-250 | 108 | 204 | 265 | 146 | 330 | 346 | 381 | 23.6 | 23.9 | 24.6 | |||||||

| -378 | CIR-108-205-250 | 205 | 27 | 27.3 | 28 | |||||||||||||

| -478 | CIR-108-305-250 | 305 | 22.1 | 22.4 | 23.2 | |||||||||||||

| 800 | -373 | CIR-89-204-315 | 89 | 315 | 204 | 1090 | 1150 | 245 | 135.5 | 350 | 366 | 410 | 170 | 130 | M12 | 27.1 | 27.4 | 28.1 |

| -374 | CIR-89-205-315 | 205 | 29.9 | 30.2 | 30.9 | |||||||||||||

| -392 | CIR-108-204-315 | 108 | 204 | 270 | 146 | 371 | 385 | 427 | 30.6 | 30.6 | 31.5 | |||||||

| -393 | CIR-108-205-315 | 205 | 34.8 | 34.9 | 35.7 | |||||||||||||

| -493 | CIR-108-305-315 | 305 | 28.6 | 28.7 | 29.5 | |||||||||||||

| 1000 | -413 | CIR-108-205-380 | 108 | 380 | 205 | 1290 | 1350 | 300 | 159 | 417 | 437 | 487 | 220 | 170 | M16 | 49.1 | 49.1 | 51.7 |

| -513 | CIR-108-305-380 | 305 | 41.6 | 41.6 | 44.2 | |||||||||||||

| -414 | CIR-108-206-380 | 206 | 48.6 | 48.7 | 51.3 | |||||||||||||

| -514 | CIR-108-306-380 | 306 | 57 | 57 | 59.7 | |||||||||||||

| -438 | CIR-133-205-380 | 133 | 205 | 325 | 173.5 | 442 | 462 | 515 | 54.8 | 54.8 | 57.8 | |||||||

| -538 | CIR-133-305-380 | 305 | 55.1 | 55.1 | 58.1 | |||||||||||||

| -439 | CIR-133-206-380 | 206 | 57.3 | 57.4 | 60.3 | |||||||||||||

| -539 | CIR-133-306-380 | 306 | 69.3 | 69.4 | 72.3 | |||||||||||||

| 1200 | -433 | CIR-108-205-465 | 108 | 465 | 205 | 1540 | 1600 | 335 | 176 | 476 | 503 | 564 | 260 | 200 | M16 | 64.7 | 64.9 | 67.9 |

| -533 | CIR-108-305-465 | 305 | 55.4 | 55.6 | 58.7 | |||||||||||||

| -434 | CIR-108-206-465 | 206 | 64 | 64.2 | 67.3 | |||||||||||||

| -534 | CIR-108-306-465 | 306 | 74 | 74.2 | 77.3 | |||||||||||||

| -458 | CIR-133-205-465 | 133 | 205 | 360 | 190.5 | 501 | 528 | 592 | 71.7 | 71.7 | 74.9 | |||||||

| -558 | CIR-133-305-465 | 305 | 72 | 72 | 75.3 | |||||||||||||

| -459 | CIR-133-206-465 | 206 | 74.7 | 74.8 | 78.1 | |||||||||||||

| -559 | CIR-133-306-465 | 306 | 89.5 | 89.6 | 93 | |||||||||||||

| -484 | CIR-159-205-465 | 159 | 205 | 390 | 207.5 | 529 | 557 | 618 | 82.1 | 82.7 | 85.8 | |||||||

| -584 | CIR-159-305-465 | 305 | 83.6 | 84.1 | 87.2 | |||||||||||||

| -485 | CIR-159-206-465 | 206 | 86.1 | 86.6 | 89.8 | |||||||||||||

| -585 | CIR-159-306-465 | 306 | 87.3 | 87.8 | 91 | |||||||||||||

| -587 | CIR-159-308-465 | 308 | 101.4 | 101.9 | 105.1 | |||||||||||||

| 1400 | -453 | CIR-108-205-530 | 108 | 530 | 205 | 1740 | 1800 | 350 | 184 | 516 | 548 | 618 | 280 | 220 | M16 | 72.8 | 72.8 | 84.3 |

| -553 | CIR-108-305-530 | 305 | 62.2 | 62.2 | 73.8 | |||||||||||||

| -454 | CIR-108-206-530 | 206 | 71.9 | 71.9 | 83.5 | |||||||||||||

| -554 | CIR-108-306-530 | 306 | 83.1 | 83.2 | 94.7 | |||||||||||||

| -478 | CIR-133-205-530 | 133 | 205 | 380 | 198.5 | 541 | 573 | 646 | 75.6 | 75.7 | 87.3 | |||||||

| -578 | CIR-133-305-530 | 305 | 77.2 | 77.2 | 88.9 | |||||||||||||

| -479 | CIR-133-206-530 | 206 | 80.3 | 80.6 | 92 | |||||||||||||

| -579 | CIR-133-306-530 | 306 | 100.9 | 101.2 | 112.6 | |||||||||||||

| -504 | CIR-159-205-530 | 159 | 205 | 410 | 215.5 | 570 | 603 | 672 | 100 | 100.6 | 105.4 | |||||||

| -604 | CIR-159-305-530 | 305 | 101.4 | 102 | 106.9 | |||||||||||||

| -505 | CIR-159-206-530 | 206 | 104.3 | 104.9 | 109.7 | |||||||||||||

| -605 | CIR-159-306-530 | 306 | 105.5 | 106.1 | 110.9 | |||||||||||||

| -607 | CIR-159-308-530 | 308 | 121.8 | 122.4 | 127.2 | |||||||||||||

FEATURES AND BENEFITS

1. Utilizing automatic welding robots for welding. Ensuring high stability, efficiency, accurate welding position and angle, as well as consistent welding quality and appearance.

2. Rollers automatic production line. A $2.8M investment in 2024 added a complete set of rollers automatic production line for extreme consistency and fast lead times.

3. Enhanced bearing seal. Revamped and enhanced standard idler seal for water-proof bearing protection.

4. The rollers are made of high-precision special steel pipes with minimal radial runout and good balance.

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Previous:

Next:

Online inquiry