PRODUCTS

Categories

Hot Products

Carrying Idler Frame

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

Our high-quality Carrying Roller Frames are engineered to provide robust support and ensure the smooth operation of your belt conveyor systems. Designed to hold the rollers that carry bulk materials, our frames help distribute the load evenly, reducing stress on individual components and preventing belt sagging. Crafted from durable, corrosion-resistant materials, our roller frames are built to withstand the harshest environments, making them perfect for industries such as mining, construction, and manufacturing. Whether your conveyor system handles heavy loads or abrasive materials, our carrying roller frames are designed to enhance efficiency, extend equipment lifespan, and minimize maintenance needs. With customizable options to suit various belt sizes and load capacities, our carrying roller frames ensure your conveyor system operates at peak performance, providing reliable and long-lasting service for all your material handling needs. Trust us to support your business with high-performance components that deliver consistent results.

Our high-quality Carrying Roller Frames are engineered to provide robust support and ensure the smooth operation of your belt conveyor systems. Designed to hold the rollers that carry bulk materials, our frames help distribute the load evenly, reducing stress on individual components and preventing belt sagging. Crafted from durable, corrosion-resistant materials, our roller frames are built to withstand the harshest environments, making them perfect for industries such as mining, construction, and manufacturing. Whether your conveyor system handles heavy loads or abrasive materials, our carrying roller frames are designed to enhance efficiency, extend equipment lifespan, and minimize maintenance needs. With customizable options to suit various belt sizes and load capacities, our carrying roller frames ensure your conveyor system operates at peak performance, providing reliable and long-lasting service for all your material handling needs. Trust us to support your business with high-performance components that deliver consistent results.

WHERE IS IT USED

Our Carrying Roller Frames are widely used across various industries, playing a crucial role in material handling systems. Key application areas include:

1. Mining

In the transportation of heavy materials like ores and coal, carrying roller frames help distribute the load evenly, ensuring smooth and stable operation of conveyor systems.

2. Construction & Aggregates

Ideal for handling construction materials and aggregates, they are built to endure harsh environments and support the transportation of bulk materials.

3. Metallurgy

In industries such as steel and aluminum production, our roller frames ensure the efficient transport of heavy materials, contributing to improved production efficiency.

In some new energy power plants (e.g. biomass power plants), Carrying Idlers with Frame is used for conveying biomass raw materials, such as straw, wood chips and so on.

4. Coal & Energy Industry

Used in coal mines and power plants, carrying roller frames support the continuous transport of coal and other raw materials, reducing system maintenance costs.

5. Logistics & Warehousing

In bulk goods and sorting centers, these frames optimize material flow and ensure efficient storage and distribution processes.

6. Agriculture & Food Processing

For the transport of agricultural products and food materials, carrying roller frames provide stable support, ensuring smooth and efficient operations on production lines.

In all these industries, carrying roller frames ensure long-term stability and reduce wear on conveyor systems, significantly boosting operational efficiency and system reliability.

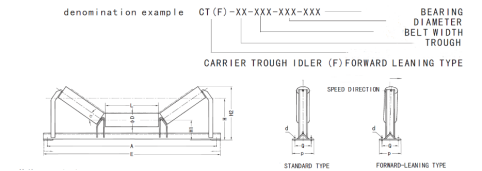

PRODUCT DESIGN

Durability: Constructed from high-strength materials like steel or other corrosion-resistant alloys, our roller frames are built to withstand harsh operating conditions, including extreme temperatures, heavy loads, and abrasive materials.

Modular Structure: Our roller frames feature a modular design, allowing for easy customization and flexibility to fit different belt sizes, load capacities, and operational requirements.

Self-aligning Rollers: Many of our roller frames are equipped with self-aligning rollers that help keep the conveyor belt properly centered, reducing the risk of belt misalignment and enhancing system efficiency.

Sealed Bearings: To minimize maintenance, some roller frames come with sealed bearings that reduce wear and tear, prolonging the life of the rollers and minimizing the need for lubrication.

Easy Maintenance: Designed for quick and easy inspection, maintenance, and replacement, our roller frames help reduce downtime and ensure uninterrupted conveyor system performance.

Energy Efficiency: The frame design is optimized to reduce friction, ensuring smooth operation and helping to lower energy consumption during the material handling process.

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

Flat carrier idlers must be designed to carrying idler frame is a key component of a belt conveyor system, providing support for the carrying idlers, which help maintain the proper tension and alignment of the conveyor belt. The structure of the carrying idler frame typically includes the following elements:

Flat carrier idlers must be designed to carrying idler frame is a key component of a belt conveyor system, providing support for the carrying idlers, which help maintain the proper tension and alignment of the conveyor belt. The structure of the carrying idler frame typically includes the following elements:

1 Frame Base

The base is the main structure that holds the other components. It’s usually made of steel and is designed to bear the load of the conveyor belt and the idlers.

2 Support Arms

These are vertical or angled arms that attach to the base of the frame and hold the idlers in place. The number and orientation of these arms can vary depending on the specific design requirements of the conveyor.

3 Mounting Points

These are where the carrying idlers are mounted onto the frame. The design of these mounting points ensures that the idlers are properly aligned with the belt and can rotate freely.

4 Adjustability Features

Many carrying idler frames allow for some adjustability in terms of height or angle, allowing the user to fine-tune the alignment of the idlers as needed.

5 Cross Beams

Cross beams are used to connect the support arms together, providing additional strength and stability to the frame. They also help ensure that the idlers remain aligned across the width of the conveyor.

6 Protective Coating

Frames are typically coated with anti-corrosion coatings, such as powder coating or galvanizing, to ensure durability in harsh environments, especially in industries like mining or heavy manufacturing.

7 Mounting Brackets

Depending on the design, there may be additional brackets or attachment points for securing the frame to the conveyor structure or other components.

8 Spacer Bars or Runners

These are used to ensure the idlers are spaced correctly and evenly, which helps in the smooth running of the conveyor belt.

TABLE OF TECHNICAL CHARACTERISTICS

|

BELT WIDTH |

MODEL |

ROLLER |

BEARING No. |

A |

E |

H |

H1 |

H2 |

P |

Q |

d |

MASS (Kg) |

||||||

|

MODEL |

D |

L |

30 |

35 |

45 |

30 |

35 |

45 |

||||||||||

|

500 |

-050-89-204 |

CR-89-204-200 |

89 |

200 |

204 |

740 |

800 |

220 |

135.5 |

286 |

300 |

328 |

170 |

130 |

M12 |

15.2 |

15.6 |

16.3 |

|

650

|

-065-89-204 |

CR-89-204-250 |

250 |

204 |

890 |

950 |

235 |

135.5 |

311 |

329 |

364 |

170 |

130 |

M12 |

17.4 |

17.5 |

18.1 |

|

|

-065-89-205 |

CR-89-205-250 |

205 |

19.1 |

19.2 |

19.8 |

|||||||||||||

|

-065-108-204 |

CR-108-204-250 |

108 |

204 |

265 |

146 |

330 |

346 |

381 |

19.9 |

20.2 |

20.9 |

|||||||

|

-065-108-205 |

CR-108-205-250 |

205 |

21.6 |

21.9 |

22.7 |

|||||||||||||

|

-065-108-305 |

CR-108-305-250 |

305 |

23.1 |

23.4 |

24.1 |

|||||||||||||

|

800

|

-080-89-204 |

CR-89-204-315 |

89 |

315 |

204 |

1090 |

1150 |

245 |

135.5 |

350 |

366 |

410 |

170 |

130 |

M12 |

22.6 |

22.6 |

23.2 |

|

-080-89-205 |

CR-89-205-315 |

205 |

24.4 |

24.4 |

25.0 |

|||||||||||||

|

-080-108-204 |

CR-108-204-315 |

108 |

204 |

270 |

146 |

371 |

385 |

427 |

25.5 |

25.5 |

26.4 |

|||||||

|

-080-108-205 |

CR-108-205-315 |

205 |

27.5 |

27.6 |

28.4 |

|||||||||||||

|

-080-108-305 |

CR-108-305-315 |

305 |

29.0 |

29.0 |

29.8 |

|||||||||||||

|

1000

|

-100-108-205 |

CR-108-205-380 |

108 |

380 |

205 |

1290 |

1350 |

300 |

159 |

417 |

437 |

487 |

220 |

170 |

M16 |

39.8 |

39.8 |

42.4 |

|

-100-108-305 |

CR-108-305-380 |

305 |

41.2 |

41.3 |

43.9 |

|||||||||||||

|

-100-108-206 |

CR-108-206-380 |

206 |

43.3 |

43.3 |

46.0 |

|||||||||||||

|

-100-108-306 |

CR-108-306-380 |

306 |

44.5 |

44.5 |

47.2 |

|||||||||||||

|

-100-133-205 |

CR-133-205-380 |

133 |

205 |

325 |

173.5 |

442 |

462 |

515 |

43.9 |

43.9 |

46.8 |

|||||||

|

-100-133-305 |

CR-133-305-380 |

305 |

44.8 |

44.8 |

47.8 |

|||||||||||||

|

-100-133-206 |

CR-133-206-380 |

206 |

46.9 |

46.9 |

49.9 |

|||||||||||||

|

-100-133-306 |

CR-133-306-380 |

306 |

48.1 |

48.1 |

51.1 |

|||||||||||||

|

1200

|

-120-108-205 |

CR-108-205-465 |

108 |

465 |

205 |

1540 |

1600 |

335 |

176 |

476 |

503 |

564 |

260 |

200 |

M16 |

52.8 |

53.0 |

56.1 |

|

-120-108-305 |

CR-108-305-465 |

305 |

54.3 |

54.5 |

57.5 |

|||||||||||||

|

-120-108-206 |

CR-108-206-465 |

206 |

56.8 |

57.0 |

60.0 |

|||||||||||||

|

-120-108-306 |

CR-108-306-465 |

306 |

58.0 |

58.2 |

61.2 |

|||||||||||||

|

-120-133-205 |

CR-133-205-465 |

133 |

205 |

360 |

190.5 |

501 |

528 |

592 |

57.6 |

57.7 |

60.9 |

|||||||

|

-120-133-305 |

CR-133-305-465 |

305 |

58.6 |

58.6 |

61.9 |

|||||||||||||

|

-120-133-206 |

CR-133-206-465 |

206 |

61.2 |

61.3 |

64.7 |

|||||||||||||

|

-120-133-306 |

CR-133-306-465 |

306 |

62.4 |

62.5 |

65.9 |

|||||||||||||

|

-120-159-205 |

CR-159-205-465 |

159 |

205 |

390 |

207.5 |

529 |

557 |

618 |

65.0 |

65.6 |

68.7 |

|||||||

|

-120-159-305 |

CR-159-305-465 |

305 |

66.0 |

66.6 |

69.7 |

|||||||||||||

|

-120-159-206 |

CR-159-206-465 |

206 |

68.6 |

69.1 |

72.2 |

|||||||||||||

|

-120-159-306 |

CR-159-306-465 |

306 |

69.8 |

70.3 |

73.4 |

|||||||||||||

|

1400

|

-140-108-205 |

CR-108-205-530 |

108 |

530 |

205 |

1740 |

1800 |

350 |

184 |

516 |

548 |

618 |

280 |

220 |

M16 |

58.9 |

58.9 |

70.5 |

|

-140-108-305 |

CR-108-305-530 |

305 |

60.4 |

60.4 |

71.9 |

|||||||||||||

|

-140-108-206 |

CR-108-206-530 |

206 |

63.3 |

63.3 |

74.8 |

|||||||||||||

|

-140-108-306 |

CR-108-306-530 |

306 |

64.5 |

64.5 |

76.0 |

|||||||||||||

|

-140-133-205 |

CR-133-205-530 |

133 |

205 |

380 |

198.5 |

541 |

573 |

646 |

64.2 |

64.2 |

75.8 |

|||||||

|

-140-133-305 |

CR-133-305-530 |

305 |

65.1 |

65.1 |

76.8 |

|||||||||||||

|

-140-133-206 |

CR-133-206-530 |

206 |

68.1 |

68.4 |

79.8 |

|||||||||||||

|

-140-133-306 |

CR-133-306-530 |

306 |

69.3 |

69.6 |

81.0 |

|||||||||||||

|

-140-159-205 |

CR-159-205-530 |

159 |

205 |

410 |

215.5 |

570 |

603 |

672 |

80.3 |

81.0 |

85.8 |

|||||||

|

-140-159-305 |

CR-159-305-530 |

305 |

81.3 |

82.0 |

86.8 |

|||||||||||||

|

-140-159-206 |

CR-159-206-530 |

206 |

84.2 |

84.8 |

89.7 |

|||||||||||||

|

-140-159-306 |

CR-159-306-530 |

306 |

85.4 |

86.0 |

90.9 |

|||||||||||||

FEATURES AND BENEFITS

1. Utilizing automatic welding robots for welding. Ensuring high stability, efficiency, accurate welding position and angle, as well as consistent welding quality and appearance.

2. Rollers automatic production line. A $2.8M investment in 2024 added a complete set of rollers automatic production line for extreme consistency and fast lead times.

3. Enhanced bearing seal. Revamped and enhanced standard idler seal for water-proof bearing protection.

4. The rollers are made of high-precision special steel pipes with minimal radial runout and good balance.

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Previous:

Next:

Online inquiry