PRODUCTS

Categories

Hot Products

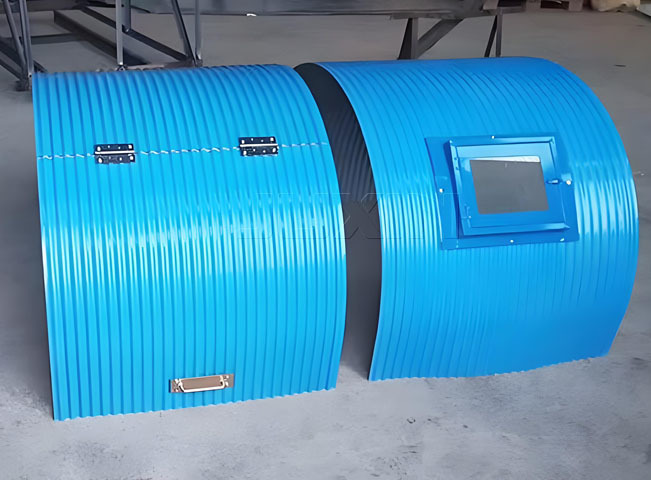

Conveyor Cover Hood

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

CConveyor cover hood, also known as conveyor belt cover or conveyor cover, is an essential part of the conveyor system, with material protection, equipment protection, safety assurance and noise reduction functions. Conveyor cover hood shields the materials being transported from natural elements like rain, dust, and sunlight. This prevents materials from getting damp, deteriorating, spilling, or being contaminated, thus ensuring their quality and integrity. For example, in the transportation of grain, the cover hood keeps the grain dry and free from dirt.

CConveyor cover hood, also known as conveyor belt cover or conveyor cover, is an essential part of the conveyor system, with material protection, equipment protection, safety assurance and noise reduction functions. Conveyor cover hood shields the materials being transported from natural elements like rain, dust, and sunlight. This prevents materials from getting damp, deteriorating, spilling, or being contaminated, thus ensuring their quality and integrity. For example, in the transportation of grain, the cover hood keeps the grain dry and free from dirt.

WHERE IS IT USED

Conveyor cover hoods have a wide range of applications in various industries. Some of the main applications are as follows:

Mining Industry

Coal Mining: In underground and open-pit coal mines, conveyor cover hoods are used to protect coal during transportation. They prevent coal dust from spreading, which not only helps to maintain a clean working environment but also reduces the risk of coal dust explosion. The cover hoods also protect the conveyor from the harsh mining environment, including moisture and rock debris.

Metal Ore Mining: For the transportation of metal ores such as iron ore, copper ore, and gold ore, conveyor cover hoods are essential. They prevent the ores from being contaminated by external substances and protect the conveyor system from the abrasive nature of the ores, thus extending the service life of the equipment.

Construction Industry

Aggregates Transportation: In quarries and construction sites, conveyor cover hoods are used to transport aggregates such as sand, gravel, and crushed stone. The cover hoods prevent the aggregates from spilling during transportation, reducing material waste and keeping the work area clean. They also protect the conveyor from the elements and from damage caused by the sharp edges of the aggregates.

Concrete Batching Plants: In concrete batching plants, conveyor cover hoods are used to transport cement, sand, and other raw materials to the mixing equipment. The cover hoods prevent dust from escaping into the atmosphere, reducing air pollution and improving the working conditions for employees.

Chemical Industry

Powder and Granular Material Transportation: In chemical plants, conveyor cover hoods are used to transport various powder and granular materials, such as fertilizers, pesticides, and chemical raw materials. The cover hoods prevent the materials from leaking and reacting with the surrounding environment, ensuring the safety of the transportation process and protecting the environment.

Corrosive Material Transportation: For the transportation of corrosive chemicals, such as acids and alkalis, conveyor cover hoods made of corrosion-resistant materials like FRP are used. These cover hoods protect the conveyor and other equipment from corrosion and ensure the safe transportation of the corrosive materials.

Recycling Industry

Waste Paper Recycling: In waste paper recycling plants, conveyor cover hoods are used to transport waste paper. The cover hoods prevent the waste paper from being scattered and contaminated, facilitating the recycling process.

Plastic Recycling: For the transportation of plastic waste in recycling plants, conveyor cover hoods are used to protect the plastic from dirt and moisture. They also help to separate different types of plastics during the transportation process, improving the efficiency of the recycling process.

PRODUCT DESIGN

The design of a conveyor cover hood involves multiple aspects such as determining the shape, selecting materials, and considering structural design and additional features. Here are the specific details:

1、Shape Design

1)Arc Shape: The arc-shaped cover hood is common, including full arc (180°), three-quarter arc (135°), and half arc (90°). The full arc cover provides the best protection, suitable for outdoor conveyors or those transporting easily contaminated materials. The three-quarter arc cover offers a balance between protection and convenience for maintenance and observation. The half arc cover is often used indoors or in environments with good conditions.

2)Flat Top Shape: Some conveyors may use a flat-top cover hood, which is simple in structure and easy to manufacture. It is suitable for occasions where the height space is limited or the requirements for material protection are not extremely high.

2、Material Selection

1)Metallic Materials: As mentioned before, galvanized steel plates are cost-effective with good corrosion resistance and strength, suitable for general industrial environments. Stainless steel plates are highly corrosion-resistant and suitable for transporting food, medicine, or corrosive materials. Aluminum plates are lightweight and corrosion-resistant, often used in places with weight restrictions.

2)Non-Metallic Materials: Fiberglass Reinforced Plastic (FRP) has excellent corrosion resistance, insulation, and anti-aging properties, ideal for corrosive or electrically sensitive environments. Plastics like polyethylene (PE) and polyvinyl chloride (PVC) are lightweight, low-cost, and easy to install, suitable for light-duty conveyors or less demanding environments.

3、Structural Design

1)Fixed Structure: The fixed cover hood is simple and firm, directly fixed above the conveyor. It is suitable for conveyors that do not require frequent access inside and have stable working conditions.

2)Retractable Structure: The retractable cover hood consists of multiple sections connected by hinges or slide rails. It can be stretched or retracted according to the conveying distance or working conditions, providing flexibility in different scenarios.

3)Folding Structure: The folding cover hood can be opened or closed by folding, usually using hinges and locking devices. It is convenient for quick access to the inside of the conveyor for maintenance, cleaning, and other operations.

4、Sealing Design

1)Sealing Strip: A sealing strip is installed around the cover hood to ensure a good seal between the cover hood and the conveyor frame, preventing dust, water, and materials from leaking. Common sealing strip materials include rubber and silicone, which have good sealing performance and durability.

2)Overlap Design: The joints of the cover hood can adopt an overlap design, where adjacent cover hood sections overlap each other to enhance the sealing effect. This design is especially important in environments where strict sealing is required.

5、Ventilation and Observation Design

1)Ventilation Holes: Appropriate ventilation holes can be designed on the cover hood to allow air circulation, preventing the buildup of heat and moisture inside the cover hood, which is beneficial for the normal operation of the conveyor and the preservation of materials.

2)Observation Windows: Transparent observation windows made of materials such as tempered glass or transparent plastics can be installed on the cover hood. This allows operators to visually inspect the operation of the conveyor and the transportation of materials without opening the cover hood.

6、Drainage Design

1)Drainage Grooves: If the conveyor is in an environment where water may accumulate, drainage grooves can be designed on the cover hood to guide the water to one side and discharge it through drainage pipes or drains to prevent water from accumulating on the cover hood and affecting its performance.

7、Safety Design

1)Anti-Fall Devices: For elevated conveyors, anti-fall devices can be installed on the cover hood to prevent the cover hood from falling off and causing safety accidents.

2)Fireproof and Explosion-Proof Design: In some special environments, such as coal mines or chemical plants, the cover hood needs to have fireproof and explosion-proof performance. This can be achieved by using fireproof and explosion-proof materials and designing appropriate ventilation and explosion-proof structures.

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

A typical conveyor cover hood consists of several main components, which are described in detail as follows:

A typical conveyor cover hood consists of several main components, which are described in detail as follows:

1 Main Cover Body

1)Arc Cover: It is usually made of metal plates like galvanized steel or stainless steel, or non-metallic materials such as FRP. The arc shape can be a full arc, three-quarter arc or half arc. For example, in some outdoor mining conveyors, a full arc cover is often used to provide comprehensive protection against the elements1.

2)Flat Cover: Some conveyors use flat-top covers, which are simple and easy to manufacture, suitable for environments where space is limited or there are no high requirements for material protection.

2 Supporting Frame

1)Metal Frame: Commonly made of steel profiles, it provides the necessary strength and stability to support the cover hood. The frame is usually installed on both sides of the conveyor and connected to the conveyor structure or the ground.

2)Composite Material Frame: In some cases where corrosion resistance and light weight are required, frames made of composite materials such as fiberglass-reinforced plastic may be used.

3 Sealing Components

1)Sealing Strip: Usually made of rubber or silicone, it is installed around the cover hood and between adjacent cover sections to prevent dust, water and materials from leaking.

2)Overlap Sealing: The joints of the cover hood adopt an overlap design, where adjacent cover sections overlap each other, enhancing the sealing effect.

4 Ventilation and Observation Devices

1)Ventilation Holes: These are distributed on the cover hood to allow air circulation, preventing the buildup of heat and moisture inside, which is beneficial for the normal operation of the conveyor and the preservation of materials.

2)Observation Windows: Made of tempered glass or transparent plastic, they are installed on the cover hood for operators to visually inspect the operation of the conveyor and the transportation of materials without opening the cover.

5 Drainage Devices

1)Drainage Grooves: If the conveyor is in a humid environment, drainage grooves are designed on the cover hood to guide water to one side and discharge it through drainage pipes or drains to prevent water from accumulating on the cover hood.

6 Auxiliary Components

1)Inspection Covers: These are installed on the cover hood and can be opened or closed for easy access to the inside of the conveyor for maintenance, cleaning and inspection.

2)Anti-Fall Devices: For elevated conveyors, anti-fall devices such as safety hooks or retaining ropes are installed on the cover hood to prevent it from falling off and causing safety accidents.

TABLE OF TECHNICAL CHARACTERISTICS

FEATURES AND BENEFITS

1. Three Decades of Expertise

Established in 1994, we bring 30+ years of specialized experience in bulk material handling equipment manufacturing and system integration, ensuring deep industry insights and technical mastery.

2. Robust China-Based Supply Chain

Leverage our vertically integrated supply network with long-term partnerships with certified Chinese steel mills, foundries, and component suppliers, guaranteeing cost efficiency, quality consistency, and on-time delivery.

3. Financial Strength & Flexible Terms

Backed by solid financial reserves, we offer tailored payment solutions for cyclical procurement (e.g., staggered payments, L/C flexibility) to optimize clients’ cash flow management.

4. Risk-Mitigated Operations

Proactive risk control frameworks minimize contractual, quality, and delivery risks: ISO 9001-certified quality assurance protocols Dual-source procurement strategies for critical components Escrow-backed performance guarantees

5. End-to-End Customization

Deliver turnkey solutions spanning design, fabrication, automation integration, and lifecycle support, tailored to site-specific requirements (e.g., extreme climates, hazardous zones).

6. After-Sales Excellence

24/7 multilingual technical support and a global spare parts network ensure <12-hour response times for critical breakdowns.

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Previous:

Next:

Online inquiry