PRODUCTS

Categories

Hot Products

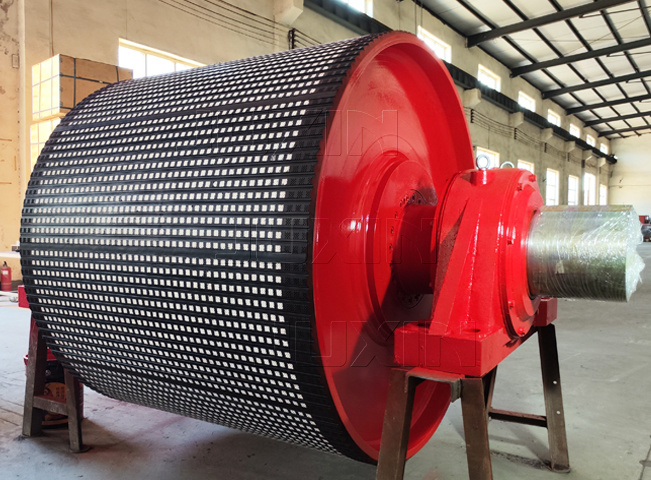

Conveyor take up pulley

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

A take-up pulley is specifically designed to maintain proper tension in the conveyor belt. It is typically located at the tail end of the conveyor and is responsible for maintaining the proper tension of the belt during operation. The take-up pulley can be adjusted to increase or decrease the tension of the belt, which helps to prevent slippage and ensure that the belt runs smoothly. Our take-up pulley is suitable for screw tension mechanism, gravity tension mechanism, and hydraulic tension mechanism.

WHERE IS IT USED

The conveyor take-up pulley is used in conveyor systems that transport materials or products from one location to another. It is commonly used in industries such as mining, manufacturing, and logistics, where large quantities of materials need to be moved efficiently and safely. The take-up pulley is typically located at the tail end of the conveyor, where it helps to maintain the proper tension of the conveyor belt. This ensures that the belt runs smoothly and prevents slippage, which can cause damage to the belt and disrupt the flow of materials.

PRODUCT DESIGN

Take-up pulleys have a design that allows for movement along the conveyor frame. This movement is necessary to accommodate changes in belt length while maintaining proper tension. The primary function of the take-up pulley is to provide a means for adjusting the tension in the conveyor belt. It compensates for changes in belt length caused by factors such as load variations, thermal expansion, and belt stretching.

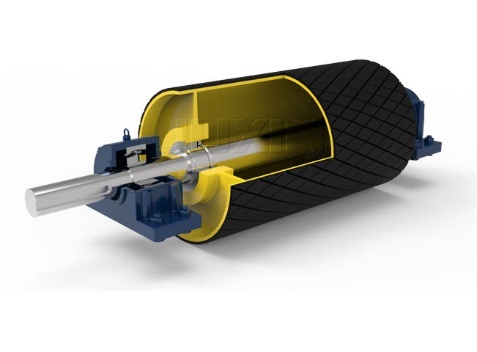

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

The structure of a conveyor take-up pulley can vary depending on the specific design of the conveyor system. However, in general, a take-up pulley consists of a cylindrical drum or roller that is mounted on a shaft.

The structure of a conveyor take-up pulley can vary depending on the specific design of the conveyor system. However, in general, a take-up pulley consists of a cylindrical drum or roller that is mounted on a shaft.

1 Shaft: It is typically supported by bearings that allow it to rotate freely.

2 Cables or Chains : The pulley is connected to a system of cables or chains that are used to adjust the tension of the conveyor belt. The cables or chains are typically attached to a counterweight or hydraulic cylinder that can be adjusted to increase or decrease the tension of the belt.

3 Locking mechanism: Some take-up pulleys may also include a locking mechanism to prevent the pulley from rotating during operation.

4 Materials: The materials used to construct the pulley can vary depending on the application, but common materials include steel, aluminum, and plastic.

TABLE OF TECHNICAL CHARACTERISTICS

|

|

||||||||||

|

BW |

D |

[T] |

[δ] |

A |

L |

L2 |

K |

Q |

P |

N |

|

500 |

250 |

0.63 |

15 |

850

|

600 |

495 |

110 |

260 |

320 |

90 |

|

315 |

1.0 |

20 |

495 |

110 |

280 |

340 |

100 |

|||

|

400 |

1.25 |

20 |

495 |

110 |

260 |

320 |

90 |

|||

|

500 |

1.6 |

30 |

495 |

110 |

280 |

340 |

100 |

|||

|

650 |

315 |

1.25 |

25 |

1000 |

750 |

570 |

110 |

260 |

320 |

90 |

|

400 |

2.0 |

35 |

570 |

110 |

280 |

340 |

100 |

|||

|

500 |

3.5 |

40 |

570 |

140 |

350 |

410 |

120 |

|||

|

630 |

4.1 |

40 |

570 |

140 |

350 |

410 |

120 |

|||

|

800 |

315 |

1.25 |

25 |

1300

|

950 |

720 |

110 |

260 |

320 |

90 |

|

400 |

2.0 |

30 |

720 |

110 |

280 |

340 |

100 |

|||

|

500 |

2.5 |

30 |

720 |

140 |

350 |

410 |

120 |

|||

|

630 |

6 |

50 |

740 |

170 |

380 |

460 |

135 |

|||

|

800 |

7 |

50 |

740 |

170 |

380 |

460 |

135 |

|||

|

1000 |

12 |

80 |

1300 |

740 |

210 |

440 |

530 |

155 |

||

|

1250 |

40 |

270 |

1400 |

870 |

350 |

640 |

780 |

240 |

||

|

1000 |

400 |

2.5 |

30 |

1500 |

1150 |

820 |

140 |

350 |

410 |

120 |

|

500 |

6.3 |

75 |

840 |

170 |

380 |

410 |

120 |

|||

|

630 |

6 |

40 |

840 |

170 |

380 |

460 |

135 |

|||

|

800 |

12 |

73 |

840 |

210 |

440 |

530 |

155 |

|||

|

1000 |

12 |

80 |

840 |

210 |

440 |

530 |

155 |

|||

|

1200 |

500 |

6.3 |

60 |

1750 |

1400 |

965 |

170 |

380 |

460 |

135 |

|

630 |

12 |

52 |

975 |

210 |

440 |

530 |

155 |

|||

|

800 |

20 |

110 |

975 |

250 |

480 |

570 |

170 |

|||

|

1000 |

27 |

160 |

1850 |

1025 |

250 |

520 |

640 |

200 |

||

|

1250 |

52 |

320 |

1900 |

1150 |

350 |

750 |

900 |

290 |

||

|

1400 |

800 |

20 |

100 |

2050 |

1800 |

1125 |

250 |

480 |

570 |

170 |

|

1000 |

27 |

160 |

2050 |

1125 |

250 |

520 |

640 |

200 |

||

|

1250 |

52 |

260 |

2100 |

1250 |

350 |

750 |

900 |

290 |

||

|

1600 |

800 |

20 |

120 |

2250 |

1235 |

250 |

520 |

640 |

200 |

|

|

1000 |

27 |

160 |

2250 |

1245 |

300 |

570 |

700 |

220 |

||

|

1250 |

66 |

450 |

2350 |

1375 |

350 |

750 |

900 |

290 |

||

|

1400 |

80 |

520 |

2350 |

1385 |

410 |

840 |

1000 |

310 |

||

|

1800 |

800 |

20 |

160 |

2450 |

2000 |

1335 |

250 |

520 |

640 |

200 |

|

1000 |

40 |

320 |

2500 |

1430 |

350 |

640 |

780 |

240 |

||

|

1250 |

66 |

450 |

2550 |

1485 |

410 |

750 |

900 |

290 |

||

|

1400 |

80 |

450 |

2550 |

1485 |

410 |

840 |

1000 |

310 |

||

FEATURES AND BENEFITS

1. Superior Material Selection

Constructed exclusively from high-grade steel alloys for optimal structural integrity and load-bearing capacity.

2. Advanced Heat Treatment

All pulley shafts undergo precision quenching processes, achieving HRC 50-60 surface hardness for extreme wear resistance.

3. Enhanced Performance Characteristics

• 30-40% increased surface hardness compared to standard rollers • Exceptional abrasion resistance reduces material degradation by up to 60% • 50% longer operational lifespan than conventional alternatives

4. Application Versatility

Suitable for extreme operating conditions including: • High-temperature environments (up to 450°C) • Heavy-load scenarios (30% above industry standard) • Corrosive atmospheres (optional coatings available)

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Online inquiry