PRODUCTS

Categories

Hot Products

Conveyor Tail Drum

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

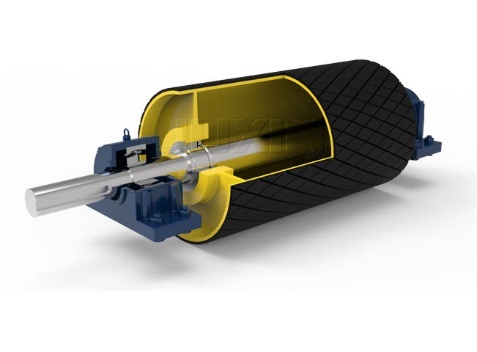

A conveyor tail pulley (return pulley) is a key component in belt conveyor systems. It is located at the end of the conveyor and is often mounted on a tensioning device to provide a point of redirection for the returning conveyor belt. A conveyor winged tail pulley is a specialized type of tail pulley in a conveyor system. It has "wings" or flanges on its sides. These flanges extend beyond the width of the conveyor belt and are designed to prevent the belt from slipping sideways off the pulley. The main body of the pulley is typically a cylindrical drum, similar to other tail pulleys. The wings are usually made of the same material as the pulley body, such as steel, and are integrated into the pulley's design.

WHERE IS IT USED

The belt conveyor tail pulley can be used as take-up pulley, snub pulley, and bend pulley. The primary function of the tail pulley is to redirect the returning conveyor belt and provide tension. It helps maintain proper belt tracking and ensures that the belt remains under tension to prevent slack. It can be used in industries such as:

mining, quarry, power plant, sand plant, cement, coal, port, steel, etc.

The belt conveyor wing pulley is known as self-cleaning pulleys. These wings serve several purposes, including improving belt tracking, reducing material spillage, and enhancing overall conveyor system efficiency. It has the ability of belt tracking and self-cleaning, and it can reduce material spillage. Like other types of conveyor pulleys, wing pulleys may be equipped with lagging material on the surface to improve traction between the pulley and the belt. It is widely used in industries such as: Aggregate & Cement, Mining, Paper & Forest, Power Generation, etc.

PRODUCT DESIGN

Load capacity: The tail drum pulley must be designed to handle the maximum load that will be placed on it. This includes the weight of the conveyor belt, the material being transported, and any additional equipment that may be attached to the conveyor.

1.Belt speed: The design of the tail drum pulley must take into account the speed at which the conveyor belt will be moving. This will affect the size and shape of the pulley, as well as the materials used in its construction.

2.Belt tension: The tail drum pulley must be designed to maintain the proper tension on the conveyor belt. This is critical for ensuring that the belt does not slip or become damaged during operation.

3.Environmental factors: The design of the tail drum pulley must take into account the environmental conditions in which it will be operating. This includes factors such as temperature, humidity, and exposure to corrosive materials.

4.Maintenance requirements: The design of the tail drum pulley must also take into account the maintenance requirements of the equipment. This includes factors such as ease of access for maintenance and repair, as well as the durability of the materials used in its construction.

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

The drum body is usually cylindrical in shape. It is made of materials such as steel, cast iron, or in some cases, aluminum for lighter - duty applications. Steel is a popular choice due to its high strength and durability. The surface of the drum body is often machined to have a smooth finish to reduce friction between the conveyor belt and the pulley. The diameter of the drum can vary depending on the specific requirements of the conveyor system. A larger diameter can help reduce the bending stress on the conveyor belt as it wraps around the pulley.

The drum body is usually cylindrical in shape. It is made of materials such as steel, cast iron, or in some cases, aluminum for lighter - duty applications. Steel is a popular choice due to its high strength and durability. The surface of the drum body is often machined to have a smooth finish to reduce friction between the conveyor belt and the pulley. The diameter of the drum can vary depending on the specific requirements of the conveyor system. A larger diameter can help reduce the bending stress on the conveyor belt as it wraps around the pulley.

1 Shaft: The shaft is at the center of the drum pulley and provides the rotational axis. It is typically made of alloy steel to handle the load and torque exerted on the pulley. The shaft must have sufficient strength to support the weight of the pulley itself, the tension of the conveyor belt, and any additional loads due to material on the belt. The shaft is usually fixed to the conveyor frame through bearings.

2 Bearings: Bearings are used to enable the smooth rotation of the pulley around the shaft. There are different types of bearings such as ball bearings and roller bearings. Roller bearings are often used for heavy - duty applications as they can handle larger radial loads. The choice of bearings depends on factors such as the load - carrying capacity, rotational speed, and the operating environment of the conveyor system. The bearings are usually housed in bearing housings that are attached to the conveyor frame to provide a stable support structure for the pulley.

TABLE OF TECHNICAL CHARACTERISTICS

|

|

||||||||||

|

BW |

D |

[T] |

[δ] |

A |

L |

L2 |

K |

Q |

P |

N |

|

500 |

250 |

0.63 |

15 |

850

|

600 |

495 |

110 |

260 |

320 |

90 |

|

315 |

1.0 |

20 |

495 |

110 |

280 |

340 |

100 |

|||

|

400 |

1.25 |

20 |

495 |

110 |

260 |

320 |

90 |

|||

|

500 |

1.6 |

30 |

495 |

110 |

280 |

340 |

100 |

|||

|

650 |

315 |

1.25 |

25 |

1000 |

750 |

570 |

110 |

260 |

320 |

90 |

|

400 |

2.0 |

35 |

570 |

110 |

280 |

340 |

100 |

|||

|

500 |

3.5 |

40 |

570 |

140 |

350 |

410 |

120 |

|||

|

630 |

4.1 |

40 |

570 |

140 |

350 |

410 |

120 |

|||

|

800 |

315 |

1.25 |

25 |

1300

|

950 |

720 |

110 |

260 |

320 |

90 |

|

400 |

2.0 |

30 |

720 |

110 |

280 |

340 |

100 |

|||

|

500 |

2.5 |

30 |

720 |

140 |

350 |

410 |

120 |

|||

|

630 |

6 |

50 |

740 |

170 |

380 |

460 |

135 |

|||

|

800 |

7 |

50 |

740 |

170 |

380 |

460 |

135 |

|||

|

1000 |

12 |

80 |

1300 |

740 |

210 |

440 |

530 |

155 |

||

|

1250 |

40 |

270 |

1400 |

870 |

350 |

640 |

780 |

240 |

||

|

1000 |

400 |

2.5 |

30 |

1500 |

1150 |

820 |

140 |

350 |

410 |

120 |

|

500 |

6.3 |

75 |

840 |

170 |

380 |

410 |

120 |

|||

|

630 |

6 |

40 |

840 |

170 |

380 |

460 |

135 |

|||

|

800 |

12 |

73 |

840 |

210 |

440 |

530 |

155 |

|||

|

1000 |

12 |

80 |

840 |

210 |

440 |

530 |

155 |

|||

|

1200 |

500 |

6.3 |

60 |

1750 |

1400 |

965 |

170 |

380 |

460 |

135 |

|

630 |

12 |

52 |

975 |

210 |

440 |

530 |

155 |

|||

|

800 |

20 |

110 |

975 |

250 |

480 |

570 |

170 |

|||

|

1000 |

27 |

160 |

1850 |

1025 |

250 |

520 |

640 |

200 |

||

|

1250 |

52 |

320 |

1900 |

1150 |

350 |

750 |

900 |

290 |

||

|

1400 |

800 |

20 |

100 |

2050 |

1800 |

1125 |

250 |

480 |

570 |

170 |

|

1000 |

27 |

160 |

2050 |

1125 |

250 |

520 |

640 |

200 |

||

|

1250 |

52 |

260 |

2100 |

1250 |

350 |

750 |

900 |

290 |

||

|

1600 |

800 |

20 |

120 |

2250 |

1235 |

250 |

520 |

640 |

200 |

|

|

1000 |

27 |

160 |

2250 |

1245 |

300 |

570 |

700 |

220 |

||

|

1250 |

66 |

450 |

2350 |

1375 |

350 |

750 |

900 |

290 |

||

|

1400 |

80 |

520 |

2350 |

1385 |

410 |

840 |

1000 |

310 |

||

|

1800 |

800 |

20 |

160 |

2450 |

2000 |

1335 |

250 |

520 |

640 |

200 |

|

1000 |

40 |

320 |

2500 |

1430 |

350 |

640 |

780 |

240 |

||

|

1250 |

66 |

450 |

2550 |

1485 |

410 |

750 |

900 |

290 |

||

|

1400 |

80 |

450 |

2550 |

1485 |

410 |

840 |

1000 |

310 |

||

FEATURES AND BENEFITS

1. Superior Material Selection

Constructed exclusively from high-grade steel alloys for optimal structural integrity and load-bearing capacity.

2. Advanced Heat Treatment

All pulley shafts undergo precision quenching processes, achieving HRC 50-60 surface hardness for extreme wear resistance.

3. Enhanced Performance Characteristics

• 30-40% increased surface hardness compared to standard rollers • Exceptional abrasion resistance reduces material degradation by up to 60% • 50% longer operational lifespan than conventional alternatives

4. Application Versatility

Suitable for extreme operating conditions including: • High-temperature environments (up to 450°C) • Heavy-load scenarios (30% above industry standard) • Corrosive atmospheres (optional coatings available)

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Online inquiry