PRODUCTS

Categories

Hot Products

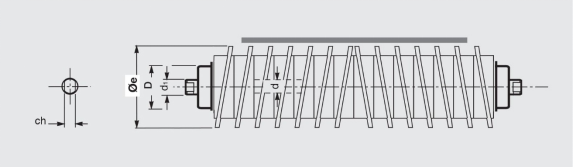

Spiral Return Roller

Leave a request and we will contact you within 10 minutes!

PRODUCT INTRODUCTION

The Spiral Return Roller is mainly used to clean the debris adhering to the conveyor belt, and it can prevent the conveyor belt from running off. The left and right spiral round steel with a welded diameter of 10mm-14mm on the top of the roller or a spiral groove cast rubber sleeve is added to the outer surface to increase the wear resistance of the entire roller, so thagtf5rdeswaqt the attachment on the top of the conveyor belt can be thoroughly cleaned, and the steel spiral roller can ensure the service life of the conveyor belt.

The Spiral Return Roller is mainly used to clean the debris adhering to the conveyor belt, and it can prevent the conveyor belt from running off. The left and right spiral round steel with a welded diameter of 10mm-14mm on the top of the roller or a spiral groove cast rubber sleeve is added to the outer surface to increase the wear resistance of the entire roller, so thagtf5rdeswaqt the attachment on the top of the conveyor belt can be thoroughly cleaned, and the steel spiral roller can ensure the service life of the conveyor belt.

WHERE IS IT USED

Used on the return transom to support the belt when the material being conveyed. The helical spiral form of the non-abrasive rings, assembled onto the base roller shell, performs a cleaning action and reduces the tendency of material to deposit itself and stick to the surface of the dirty side of the belt. They may be employed on any part of the return belt section in the case of short conveyors. On long sections it is satisfactory to employ these rollers only up to the point where the material does not adhere any more to the belt surface.

PRODUCT DESIGN

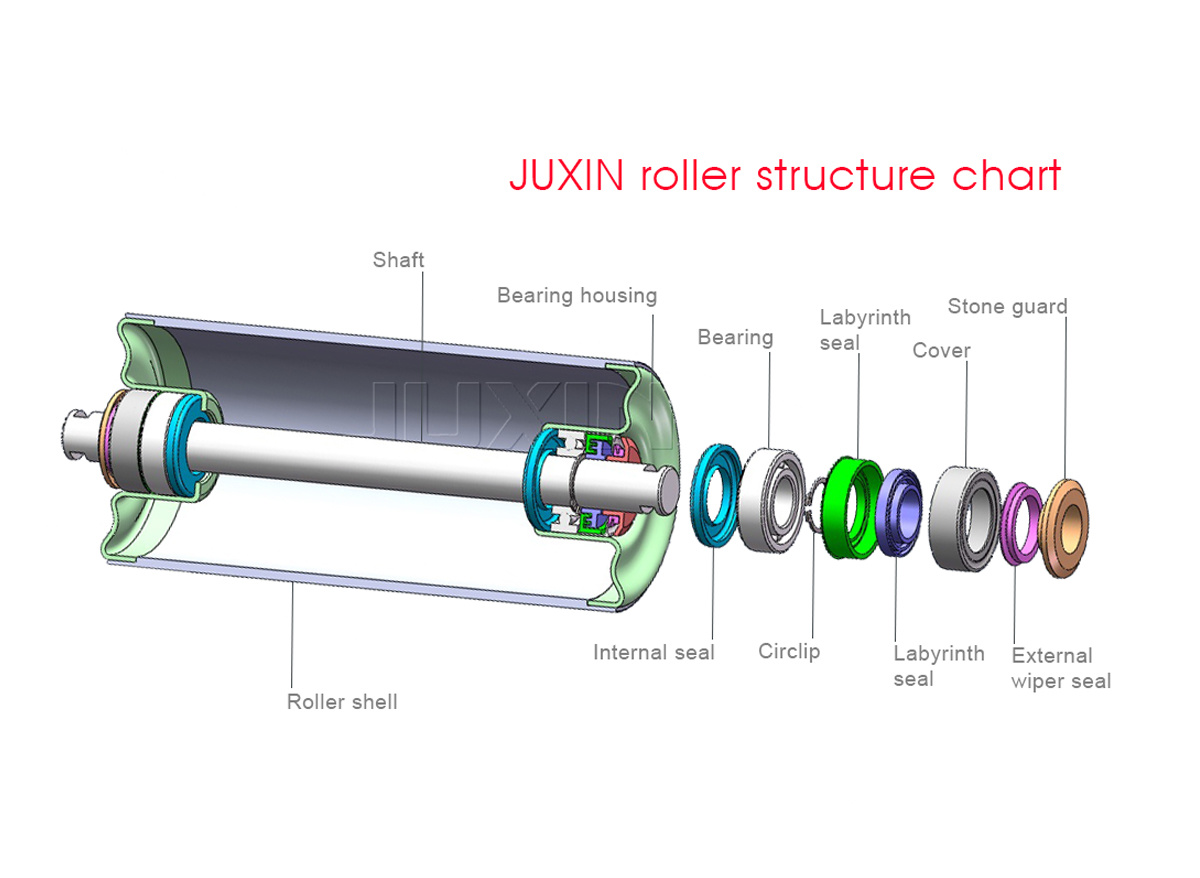

The long-life and high-sealing rollers designed and produced by JUXIN are primarily developed to address the current issues in belt conveyor roller manufacturing, including low accuracy, high rotation resistance coefficient, excessive running noise, poor sealing, and inadequate design life. The rollers feature a fully sealed, waterproof, and dustproof structure, with the bearing assembly utilizing high-precision bearing chambers and special high-quality bearings. They offer advantages such as refined structure, low noise, maintenance-free operation, extended service life (over 30,000 hours), and reliable performance. Therefore, they are an excellent choice for advanced belt conveyor systems.

THE CONVEYOR BELT HAS THE FOLLOWING DESIGN

1 Pipe: This is the main part of the roller, typically constructed from steel pipe and coated with paint to enhance its anti-corrosion and wear resistance properties.

1 Pipe: This is the main part of the roller, typically constructed from steel pipe and coated with paint to enhance its anti-corrosion and wear resistance properties.

2 Bearings: Deep groove precision ball bearings, DIN 62 and 63 series, 6204, 6205, 6305, 6206, 6306, 6308, C3 or C4 clearance.

3 Seal: Labyrinth seal, its purpose is to prevent dust and debris from entering the bearing interior, three-lip type, material ISOPA6 (nylon 6).

4 Bearing housing: This component connects rollers to conveying equipment, available in fixed and adjustable types.

5 Shaft: Cold drawn steel. Raw steel rod grinders process shafts with diameters up to 20, 25, 30, 40 (ISO h6 or g6 tolerances apply to seal parts or entire shafts).

6 Lubrication: The roller assembly using waterproof, dust-proof, long-acting 3 class lithium grease, long-term lubrication.

7 Circlip spring: Made of spring steel, it serves to secure the movement of roller strings.

Collectively, these components form a complete structure that effectively supports conveyor belts and material weight while maintaining normal belt conveyor operation.

TABLE OF TECHNICAL CHARACTERISTICS

|

|

||||||

|

Roller No. |

D |

inch |

s |

Bearing housing |

d |

Bearing |

|

|

mm |

|

mm |

δ |

mm |

|

|

JXGR1 |

63 |

|

3 |

2.5 |

20 |

6204 C3 |

|

76 |

3 |

3 |

||||

|

89 |

|

3 |

||||

|

102 |

4 |

3 |

||||

|

108 |

|

3.5 |

||||

|

114 |

4.5 |

3.5 |

||||

|

127 |

5 |

4 |

||||

|

133 |

|

4 |

||||

|

140 |

|

4 |

||||

|

JXCR 2 |

76 |

3 |

3 |

3 |

25 |

6205 C3 |

|

89 |

|

3 |

||||

|

102 |

4 |

3 |

||||

|

108 |

|

3.5 |

||||

|

114 |

4.5 |

3.5 |

||||

|

127 |

5 |

4 |

||||

|

133 |

|

4 |

||||

|

140 |

5.5 |

4 |

||||

|

152 |

6 |

4 |

||||

|

159 |

|

4.5 |

||||

|

168 |

|

4.5 |

||||

|

JXCR3 |

89 |

|

3 |

3.5 |

25 |

6305 C3 |

|

102 |

4 |

3 |

||||

|

108 |

|

3.5 |

||||

|

127 |

5 |

4 |

||||

|

133 |

|

4 |

||||

|

140 |

5.5 |

4 |

||||

|

152 |

6 |

4 |

||||

|

159 |

|

4.5 |

||||

|

168 |

|

4.5 |

||||

|

JXCR4 |

89 |

|

3 |

3.5 |

30 |

6206 C3 |

|

102 |

4 |

3 |

||||

|

108 |

|

3.5 |

||||

|

127 |

5 |

4 |

||||

|

133 |

|

4 |

||||

|

140 |

5.5 |

4 |

||||

|

152 |

6 |

4 |

||||

|

159 |

|

4.5 |

||||

|

165 |

6.5 |

4 |

||||

|

168 |

|

4.5 |

||||

|

JXCR5 |

89 |

|

3 |

4 |

30 |

6306 C3 |

|

108 |

|

3.5 |

||||

|

133 |

|

4 |

||||

|

159 |

|

4.5 |

||||

|

JXCR6 |

108 |

|

4 |

5 |

40 |

6308 C3 |

|

133 |

|

4 |

||||

|

159 |

|

4.5 |

||||

|

165 |

6.5 |

4 |

||||

|

194 |

|

6.3 |

||||

FEATURES AND BENEFITS

1. Utilizing automatic welding robots for welding. Ensuring high stability, efficiency, accurate welding position and angle, as well as consistent welding quality and appearance.

2. Rollers automatic production line. A $2.8M investment in 2024 added a complete set of rollers automatic production line for extreme consistency and fast lead times.

3. Enhanced bearing seal. Revamped and enhanced standard idler seal for water-proof bearing protection.

4. The rollers are made of high-precision special steel pipes with minimal radial runout and good balance.

INSTALLATION AND COMMISSIONING FROM PROFESSIONALS

JUXIN also provides services for the installation and commissioning of conveyor equipment. Our team of experienced specialists will efficiently set up the operation of the conveyor line at your enterprise in a timely manner. We also offer installation supervision, where our specialist will visit your facility after equipment delivery to oversee the installation and launch process carried out by your personnel.

PRE-SALES:EQUIPMENT SELECTION

Assisting customers in selecting the most suitable belt conveyor for their specific needs and requirements. Additionally, we offer technical advice and guidance to facilitate informed decision-making on bulk material handling equipment. Furthermore, we can provide the following information:

• Customized solutions and design services

• Delivery lead time

• Equipment operation and maintenance

• Environmental and safety measures

• Integration with existing equipment

AFTER-SALES: 24/7 HOTLINE SUPPORT

We have established a hotline (+86 18622502901) to promptly address customer inquiries, feedback, and complaints. Our support is available 24 hours a day, seven days a week. Generally, our engineers will work remotely to resolve your issues.

- We provide training for customers on effective and safe operation and maintenance of the belt conveyor.

- We offer technical support and troubleshooting assistance to address any operational issues or concerns with the belt conveyor.

- We supply spare parts and components as needed, ensuring prompt delivery and compatibility with the specific belt conveyor model.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

PHOTO GALLERY

Previous:

Online inquiry